Wastewater treatment for chemical plant, and case studies

In the past, industries with many heat-intensive processes, such as the steel and petrochemical industries, were called "water-intensive industries" because they used a lot of cooling and cleaning water.

Today, however, advanced treatment technology for trace amounts of toxic substances and organic solvents in wastewater has become essential and must be strictly controlled in many machinery, electronics, and other industries, regardless of the amount of discharge.

【Petrochemical plant, etc.】

Most wastewater is process wastewater, including raw materials, intermediate products, and catalysts from various plants, and acidic or alkaline cleaning wastewater.

In many cases, treatment methods are established for each substance contained and drainage route, and proper treatment is required.

【Electronic industry】

There are two types of wastewater: inorganic wastewater, such as fluorinated wastewater and acid/alkali wastewater, and organic wastewater, such as organic solvents.

【Plating plant】

Wastewater containing toxic substances generated in pretreatment processes such as degreasing, pickling, and surface preparation, as well as in the plating process, is treated as wastewater.

【Automotive industry】

Painting processes generate wastewater from degreasing, paint booth, electrodeposition coating, and other painting wastewater.

Wastewater treatment methods for chemical plant, etc.

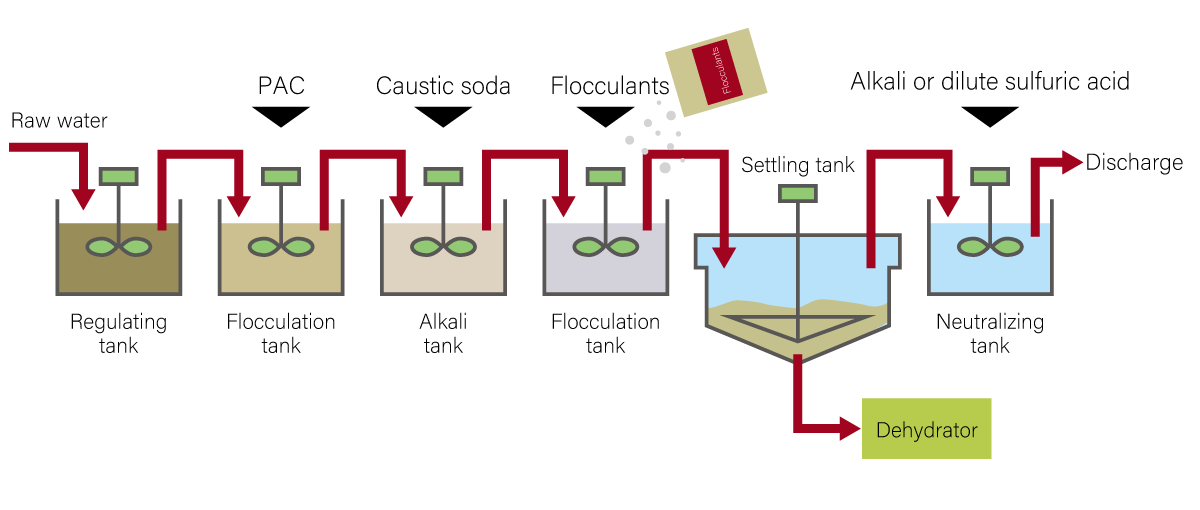

【Petrochemical plant, etc.】

In many cases, treatment methods are established for each substance contained and wastewater route, and treatment facilities are provided for proper management within factories and plants.

In recent years, efforts to control and reduce waste generation have become more sophisticated, especially at each business site and production line, and the role of chemicals used for wastewater treatment has become increasingly important.

【Electronic industry】

Inorganic wastewater is generally treated by coagulation sedimentation after neutralization with salt and pH adjustment, while organic wastewater is generally treated by biological treatment.

【Plating plant】

Depending on the type of toxic substances, cyanide wastewater, chromium wastewater, and acid/alkali wastewater are generally treated separately, and heavy metals are treated by precipitating as hydroxide.

In recent years, technologies for recovering these metals have been studied, and purification and extraction to increase purity are being considered.

【Automotive industry】

The treatment method is designed to remove oils and fats, and it is generally biological treatment after flocculation and pressurized flotation tanks, followed by sedimentation coagulation, filtration, and final treatment with activated carbon.