Mining wastewater treatment and case studies

Due to resource depletion and the development of international trade in resources, most coal and metal mines in our country have closed.

However, since natural spring water is discharged from these closed mines, the owners are obliged to treat the wastewater to prevent mining pollution.

Mining drainage, which is highly acidic and contains heavy metals, is discharged from mining sites that once produced a variety of metallic minerals such as gold, silver, copper, and lead, causing water pollution of rivers and soil contamination of agricultural land.

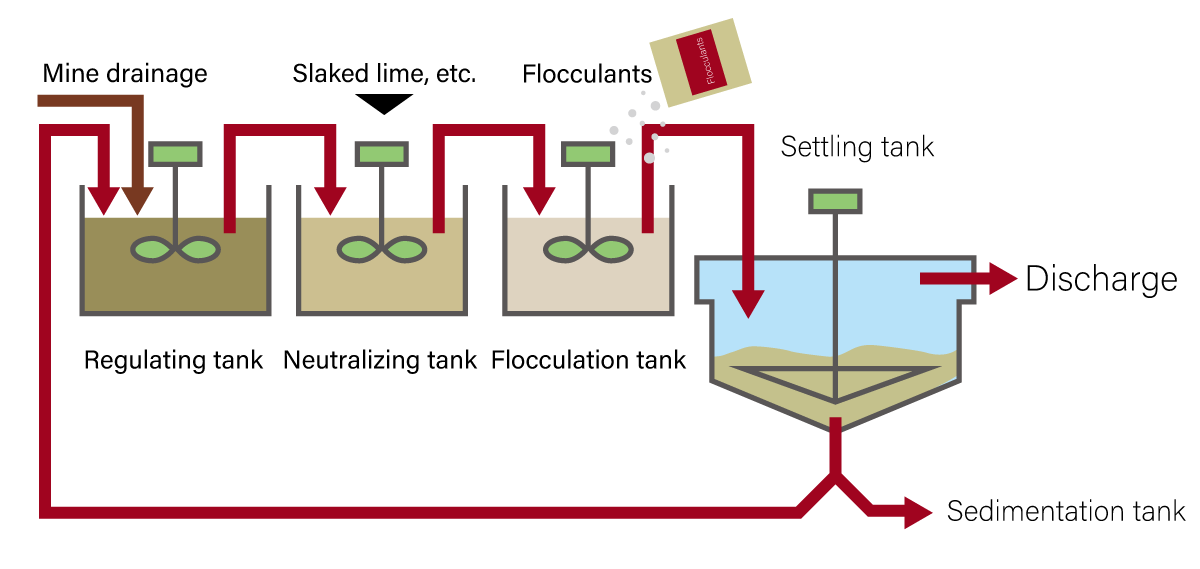

Wastewater treatment methods

The treatment of mine drainage that is acidic and contains metals requires two processes: neutralization and removal of heavy metals.

The method, commonly referred to as the neutralization method, involves a process of neutralization with an alkali agent and a solid-liquid separation process that precipitates and removes the metals precipitated in the form of hydroxides